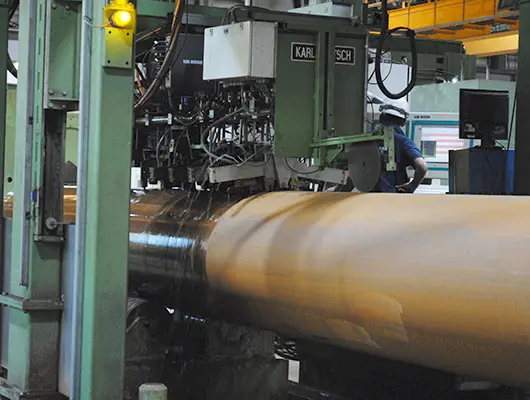

Process Pipes

Reliable solutions for challenging environmental conditions

Our modern production facilities make it possible for us to manufacture steel pipes for the oil, gas, chemical and power generating industries in an extremely wide variety of materials. This includes high and low-alloyed steels as well as stainless steel in addition to classic carbon steels. These pipes are manufactured in accordance with API, ASTM and EN norms as well as in accordance with individual customer requirements.

EEW Solutions for Process Pipes

Other special services

|

NACE MR 0175 / ISO 15156 |

|

|

NACE TM 0284 (HIC) |

|

|

NACE TM 0177 (SSCC) |

|

|

Full Ring Test (OTI 95 635) |

|

|

HIC / SSC acceptance criteria |

|

|

other services according to customer requirements |

Applications for Process Pipes

Pipe grades

|

check ASTM A671 including belonging supplementary requirement |

|

|

check ASTM A672 including belonging supplementary requirement |

|

|

check ASTM A691, including 5CR, 9CR, Grade 91, including belonging supplementary requirement |

|

|

check API 5L including belonging supplementary requirement |

References

Interested in our products?

Get in touch with our Sales Team.