Expertise & Know-How

The Development of New Dimensions

Comprehensive solutions for your demanding projects

A successful project not only includes the manufacture of a high-quality and technically demanding product. Welding alone is not only what makes us a reliable partner that our customers have been relying on for decades.

It is the synergy of comprehensive project management, continuous development of processes, and precise work along the entire value chain that makes our products such high-quality.

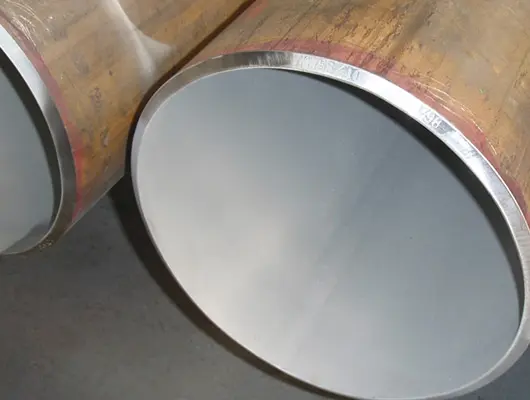

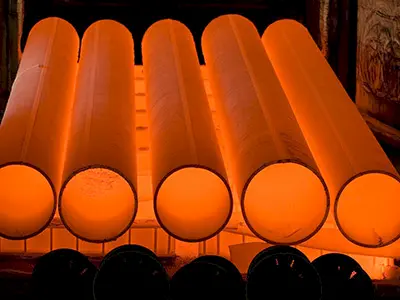

Product quality

Delivering a consistently high quality of our products is our biggest goal. This is the only way we can guarantee the durability and longevity of our pipes and ensure that our customers and their projects are always ready for use. To achieve this, we continuously improve our production steps, work only with high-quality materials and regularly train our employees.

Project Management

Whether it´s an XXL monopile with a diameter of 12 m or filigree Clad pipe with a diameter of only 35 cm - every customer project is individual and equally important to us. For this reason, we adapt our project management individually to each project. Our organization is dynamic, so that we are always able to form a project team for each order. These teams are interdisciplinary and not only include members from one location, but often from the entire EEW Group. Thus, we have the possibility to rely on comprehensive, group-wide know-how.

Even before the first plate starts to be produced, we provide our customers with comprehensive advice. We carefully examine the technical properties and specifications of the pipe and identify any potential to make our customer projects even more successful.

Supply Chain

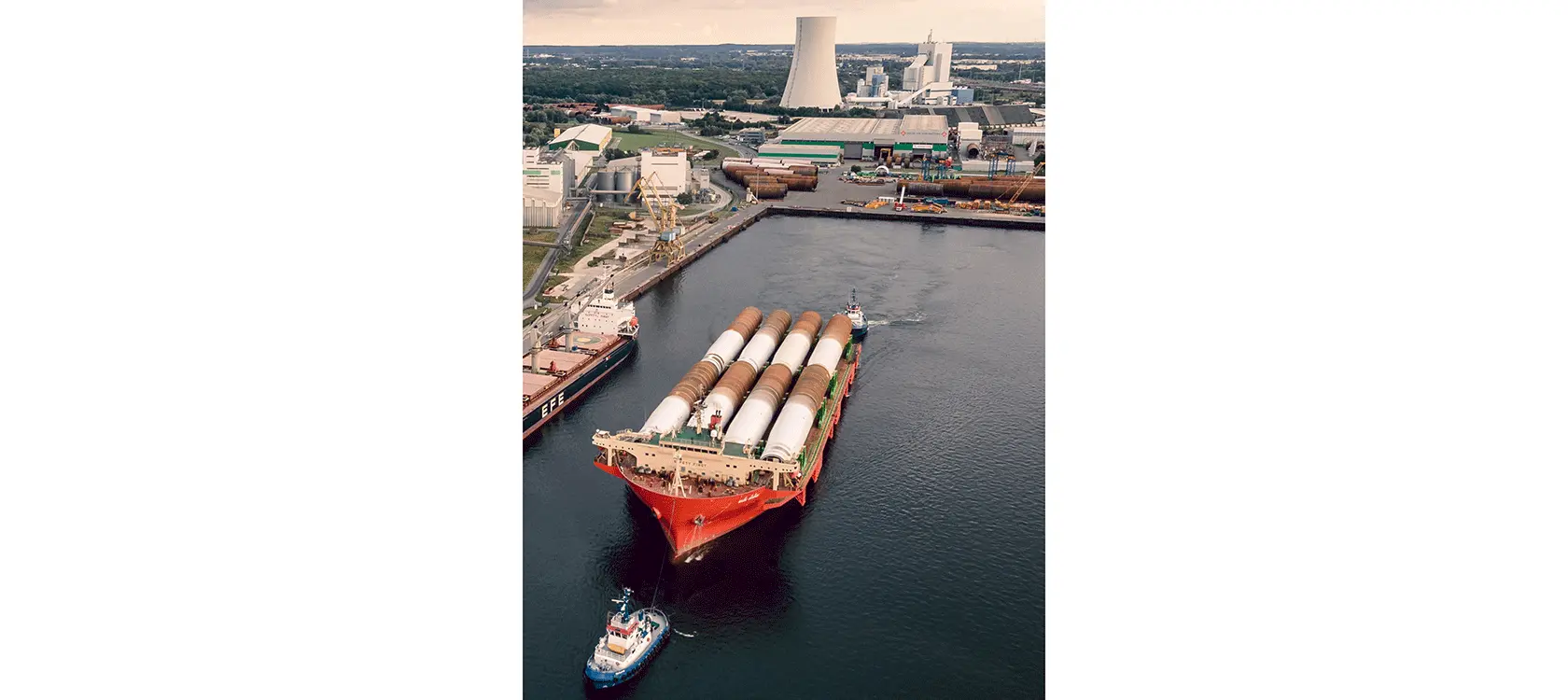

A reliable and well-organized supply chain is now more important than ever. In order to support our customers through the production of high-quality pipes and pipe components, we continue to organize the supply chain around our product. We provide our customers with full service with everything to do with pipes. This means that additional manufacturing or service steps are managed from a single point of contact. These steps include, for example, the production of bends, special coatings such as concrete coatings, or the attachment of components such as cones. We also take care of the transport of the pipes to subcontractors and finally to the project destination. It goes without saying that in all of these processes we work exclusively with qualified suppliers who are regularly audited by us.

Group-wide know-how

With six plants and 17 sales offices worldwide, we are globally networked and always have an ear to the various markets. We trust and rely on our group-wide knowledge and constatly exchange ideas to improve it. This enables us to manufacture projects at several locations. Furthermore, our employees can work in our different plants and thus share their personal knowledge with international colleagues.

Construction Service

For more than 50 years in the steel pipe business, the EEW Group has been one of the leading manufacturers of SAW pipes. To maintain this position in the future, we not only supply our customers with steel pipes of the highest quality, but also support them with complete solutions for their ambitious projects.

Point-to-Point Construction Service

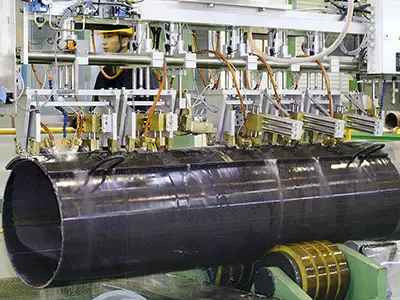

Volatile market conditions and challenges in terms of pricing, flexibility and fast delivery are important factors for the success of projects. To meet these customer requirements and to support our clients in the best possible way, we have developed our Point-to-Point Construction service. This service comprises the pre-fabrication of pipe components, from detailed engineering to pipe production and the organization of transport. At an early stage of the project, EEW begins the pre-planning in close cooperation with the customer. Using detailed engineering, ideal solutions are developed together. With the start of pipe production, the key activity of our Point-to-Point Construction Service comes into play - the assembly of the ready-to-install pipe components.

In addition to single pipe lengths, structural pipe components can be delivered with the following complete or single services:

- Cutting to fixed lengths, machining and tapering of the ends

- Circumferential welding

- Production and assembly of add-on components, such as cones, shim plates, reinforcement rings, etc.

- Weld beads

- End profiling

Benefits of our Point-to-Point Construction Service

With our Point-to-Point Construction Service, we make it possible for you to stay ahead of your competition by improving the following competitive factors:

Cost efficiency

- Shorter production time

- No interferences at the yard

- Minimal wastage

Project schedule

• Shorter fabrication time at the yard

• Simultaneous construction work is possible

Quality

• Controlled production conditions

• Recurring processes

• Highly-qualified workforce

Safety and Environment

• Elimination of weather conditions

• Reduction of work at elevated heights

• Reduction of wastage and transport

Ready-for-installation service

To facilitate the production process at sea, EEW offers its customers ready-to-install service. This service includes machining measures such as marking and applying attachment parts such as weld beads. This means that the products can be transported directly to the installation site and do not have to be handled in the yard. With this service our customer can safe a great deal of time.

Success Stories

Questions to our products and services?

Get in touch with our technical team.