Hard shell - stainless core

Clad Pipes

Complex process of metal bonding

Cladding refers to a process in which a metal, CRA or composite (the cladding material) is mechanically or metallurgically bonded to another dissimilar metal (the backing material) to increase its resistance (e.g. to corrosion) on the one hand and its strength on the other. The majority of clad products manufactured today combines carbon steel for the backing material and e.g. aluminum, nickel, nickel alloys, copper, copper alloys or stainless steel for the cladding material to be bonded. Typically, the purpose of the clad is to protect the underlying steel material from the transported medium. The cost of using clad pipes in pipeline projects is therefore only a fraction of the cost of what it would cost to use a more expensive solid steel alloy for the entire product.

14 - 96

inch outer Diameter

0.375

inch min. Wall Thickness

2.00

inch max. Wall Thickness

~ 140 K

produced Tonnage 2017-2022

Materials

|

check all API grades & CRA layer grades as per customer specification such as Alloy 625, Alloy 825, TP316L, etc. |

|

|

check all DNV grades & CRA layer grades as per customer specification such as Alloy 625, Alloy 825, TP316L, etc. |

|

|

check ASTM A671 / ASTM A672 & CRA layer grades as per customer specification such as Alloy 625, Alloy 825, TP316L, etc. |

|

|

check further material grades and combinations can be processed per customer specification |

Increasing importance of Clad pipes

Driven by the fact that the remaining energy reserves are located in deeper waters and further from shore, more than around 70% of them are corrosive, much more corrosive than the reservoirs being exploited onshore. Engineers act on the assumption than corrosion contributesto more than 50% of offshore pipeline failures. This is because the internal reservoir fluids and gases do significantly increase the corrosion of a conventional pipeline. The ingredients of these gases and fluids are typically aggressive elements such as chlorides, sand, organic acids, carbon dioxides (sweet crude) and hydrogen sulfides (sour crude). While CRA are commonly used to combat corrosion of pipes in sweet and sour crude mediums, nickel based alloys are rather used for resistance to ultra-sour fluids and gases. In addition, the high temperatures and pressures encountered in the subsea well can lead to corrosion in pipelines and risers which are unavoidable to get oil and gas products to the consumers.

Combination of Corrosion Resistance and Toughness

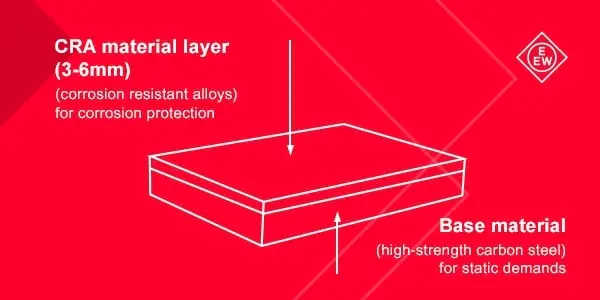

Environmental conditions such as corrosive medium, growing safety requirements and project cost pressure have changed the dynamics and demands in the pipeline industry. Clad materials combine the corrosive and/or wear resistance properties of corrosion resistant alloys (CRA) respectively high-alloyed materials with the high strength and toughness of carbon manganese steels. This combination results in potential reductions of the total wall thicknesses as well as a minimized need for CRA material both leading to significant cost savings of up to 70% or more, depending upon steel grade and wall thickness.

Reasons to partner with EEW Group

References

Success Stories

Interested in our products?

Get in touch with our Sales Team.