Building the foundation of tomorrow´s energy supply

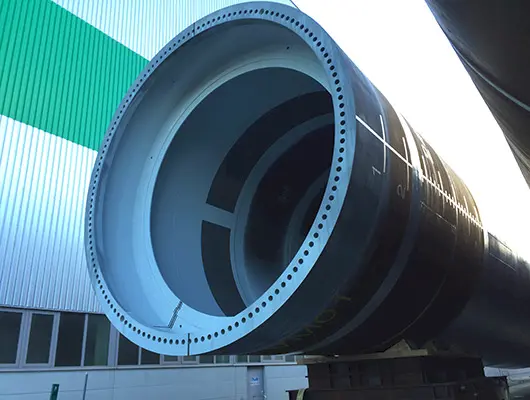

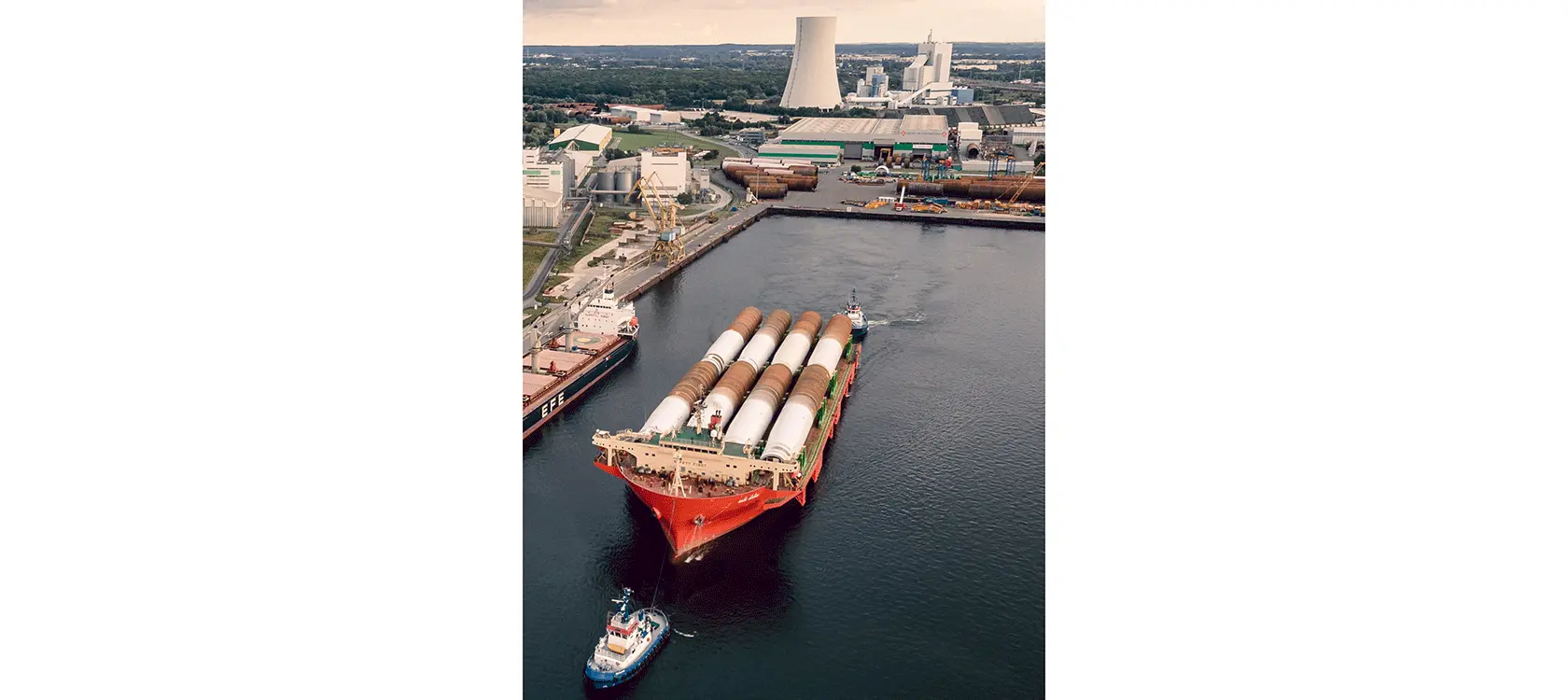

Monopiles

More diameters for the energy of tomorrow

As a pioneer in the production of monopiles, our customers can rely on long-term manufacturing knowledge gained from the completion of more than 70 offshore wind projects. With a production capacity of more than 200 monopiles per year, the EEW Group is able to contribute significantly to the global expansion of offshore wind energy. Since 2008, EEW Special Pipe Constructions GmbH, located in Rostock, Germany, has supplied foundations for offshore wind projects worldwide. With EEW American Offshore Structures, founded in 2020 in New Jersey, USA, the EEW Group is ready to supply the fast growing US-American offshore wind market with high-quality monopiles.

Reasons to partner with EEW Group

The rising global demand for energy is driving growth in offshore wind turbines installation. Consequently, the size of the monopiles that are the foundations for these turbines is also increasing. As the world's leading manufacturer of large-diameter pipes, EEW has both state-of-the-art technical equipment and extensive know-how to anticipate these trends early on and to offer customers the ideal solution for their project. Our EEW monopiles are produced from high-quality steel plates. Thus we are able to process all common offshore grades starting at S355 up to S460 and above.

Reasons to partner with EEW

References

Success Stories

Interested in our products?

Get in touch with our Sales Team.